Continuous Improvement is the process of constantly seeking better ways to deliver value, solve problems, and enhance performance. It’s a mindset and a methodology that pushes individuals, teams, and organizations to learn from experience, study results deeply, and evolve regularly.

Rooted in the work of Walter A. Shewhart and later refined by his student Dr. W. Edwards Deming, continuous improvement is not about perfection—it’s about progress. It’s the quiet force behind world-class quality, long-term innovation, and high-performing teams.

“It is not enough to do your best; you must know what to do, and then do your best.” – W. Edwards Deming

Continuous Improvement and Innovation: What’s the Connection?

While innovation often gets the spotlight for bold breakthroughs, continuous improvement is its quiet companion—making those breakthroughs possible through consistent learning and iteration.

Innovation is not just about new ideas or products—it’s about the ongoing effort to improve them. Every innovation cycle is built on the lessons of previous attempts. That’s why continuous improvement is the engine of innovation.

What is the PDSA Cycle?

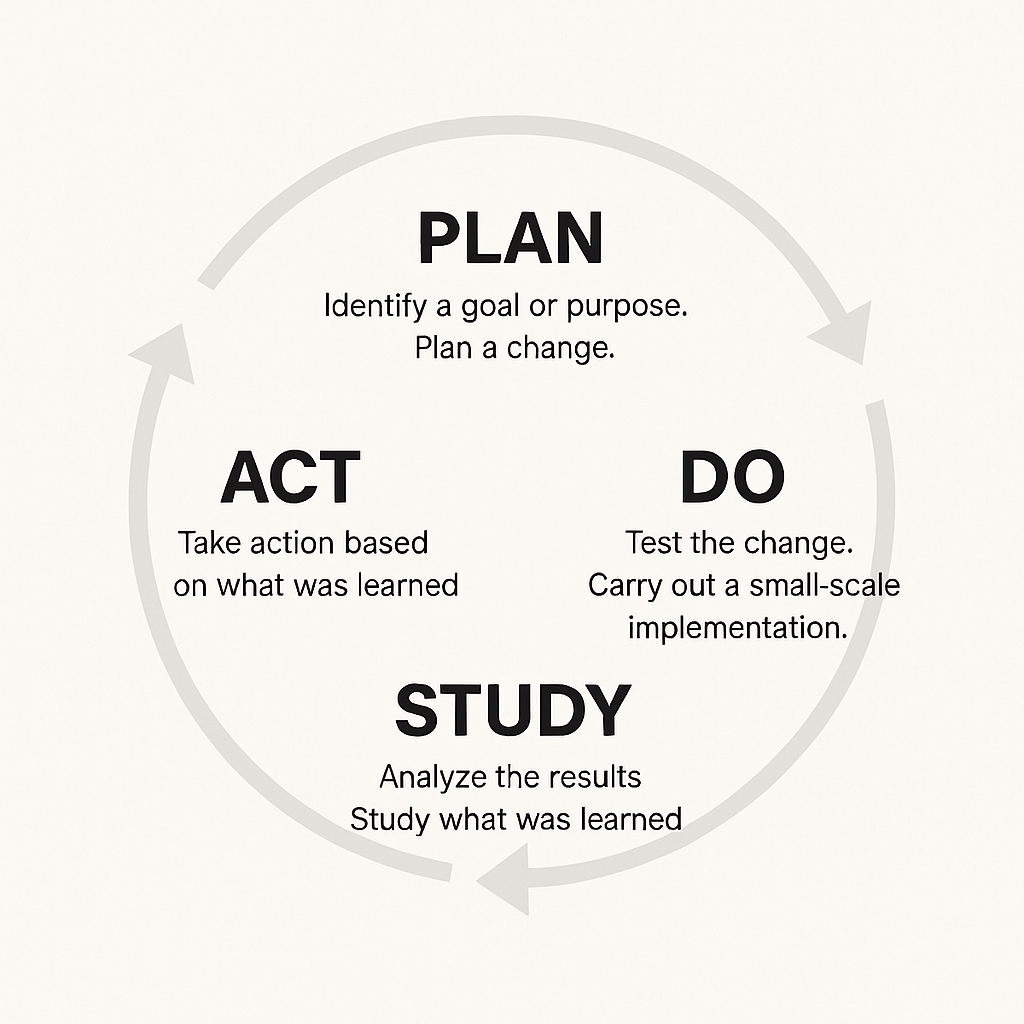

The PDSA Cycle (Plan–Do–Study–Act) is the core method of continuous improvement. Originally developed by Walter Shewhart and refined by Deming, it is a powerful framework for testing changes, learning from results, and making informed adjustments.

- Plan

- Identify a problem or opportunity. Set a clear objective, gather data, and develop a theory for improvement. This phase includes forming a diverse team and understanding the system you’re trying to change.

- Do

- Implement the change on a small scale. This is a test—not a final rollout. Collect observations and data as the plan unfolds.

- Study

- Analyze the data. Reflect not just on what happened, but why it happened. What were the unintended outcomes? What can you learn from this trial?

- Deming insisted on “Study” over “Check” because study invites inquiry, understanding, and reflection. “Check” too often becomes a box-ticking exercise, devoid of insight.

- Act

- Based on what you learned, refine the change or abandon it. If successful, integrate it more widely and set a new goal—starting the cycle again.

Why “Study” Matters More Than “Check”

Many organizations unknowingly undermine improvement by treating it as a compliance task. They “check” if results were met, but rarely study them deeply enough to learn something new.

Deming believed that true learning requires thoughtful reflection and analysis. The “Study” phase is where innovation is born—where teams find patterns, insights, and new opportunities that aren’t obvious on the surface.

The Power of People and Diverse Perspectives

Continuous improvement isn’t just a technical process—it’s a social process. The best solutions come when diverse voices come together to challenge assumptions, share experiences, and see the system from different angles.

Bringing in people from different departments, backgrounds, or even industries allows for more innovative thinking and fewer blind spots. As Deming emphasized, the majority of problems in a system are due to the system itself—not the people. But solving those problems requires the insight of the people working in it.

Continuous Improvement as a Culture

Sustainable improvement isn’t driven by one-off projects or occasional efforts. It requires a culture of curiosity, psychological safety, and shared purpose.

That’s why companies known for innovation—like Toyota, Amazon, and 3M—also invest heavily in process improvement, team learning, and feedback loops. They understand that small, daily improvements fuel the big leaps that change industries.

Key Takeaways

- Continuous improvement is the backbone of sustainable innovation.

- The PDSA Cycle helps organizations learn from experience and make evidence-based changes.

- “Study” means reflecting deeply—not just ticking boxes.

- Involving diverse voices leads to richer solutions and a more innovative culture.

- Innovation isn’t a one-time event—it’s a continual commitment to doing better.